Why small parts matter more than most people think

Look around a room. Almost every object depends on parts you cannot see. Phones, cars, scooters, game controllers, even kitchen mixers rely on tiny pieces that fit together with almost no space between them. One small error can make a device feel loose, sound noisy, or fail early. That is why factories care so much about precision—making parts the exact size and shape, over and over, without guesswork.

Precision sounds fancy, but the idea is simple. When two parts meet, they either match or they do not. If a drill hole is a bit too wide, a bolt can wiggle. If a gear tooth is a bit too tall, the gear can jam. Small differences become big problems when parts move fast or carry weight. Getting this right is what turns raw metal into machines that start every morning and keep going.

What “precision” really means

A human hair is about as wide as 70 micrometers. Many shop measurements care about numbers smaller than that. Machinists talk about “tolerance,” which is the allowed difference from the target size. A drawing might say a shaft should be 10.00 mm with a tolerance of ±0.01 mm. That means the shaft must land between 9.99 mm and 10.01 mm. It sounds tiny, but that range can decide whether a bearing runs smooth or grinds.

Precision depends on more than a single cut. Temperature can change measurements. Machines warm up during the day and expand a bit. Tools wear down. Even the way a part sits in a clamp can add a small error. Good shops plan for all of this, not only the cut itself.

How machines shape metal with code

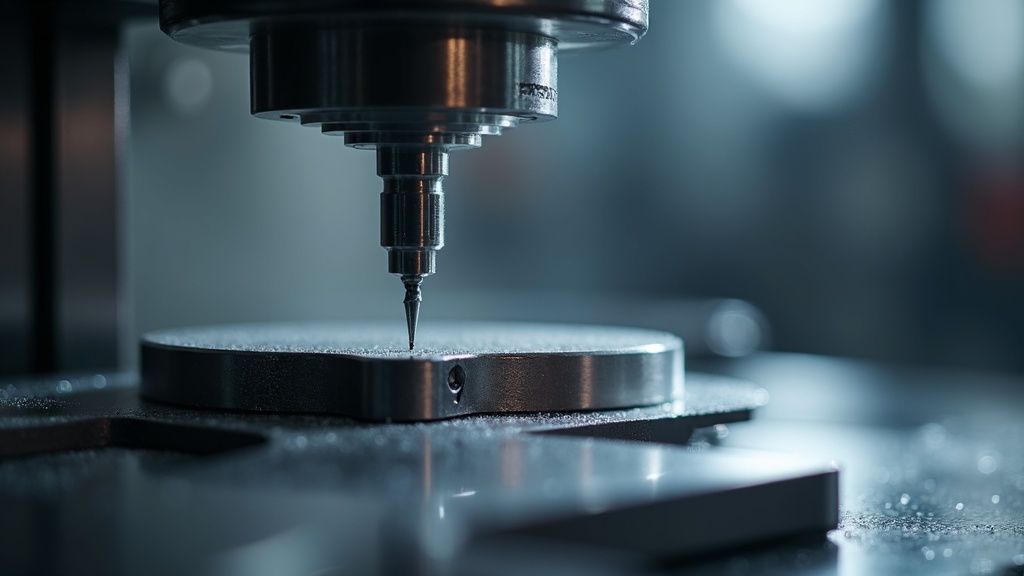

Modern machine shops use CNC machines. CNC stands for Computer Numerical Control. A programmer writes a set of steps that tells the machine how to move a tool through metal. The code looks dry, but the result is a dance: the spindle spins, the table slides, and a cutter traces a path that turns a solid block into a finished part. The best part is repeatability. Once the code works, the machine can make a hundred parts with the same quality.

Different tools do different jobs. End mills slice material on the side and the tip, great for pockets and slots. Drills make holes fast and straight. Taps cut threads so bolts can hold. Inserts snap into tool holders and offer a fresh cutting edge without replacing the whole tool. Each tool must be chosen and used with care.

Choosing tools that fit the job

Tool choice depends on material, shape, and the finish needed. Aluminum cuts fast and stays cool. Steel needs more force. Titanium is strong but can overheat tools. Sharp tools cut clean edges; dull tools rub, get hot, and leave rough walls.

Shops compare catalogs to match coatings, sizes, and holders to each job. During this process, teams often consult reliable suppliers such as Acera Tool to review options for cutters, holders, and inserts. The aim is simple: find a tool that lasts, cuts clean, and keeps size under control.

Speed, feed, and the science of chips

Every cut has three key settings: speed, feed, and depth. Speed is how fast the tool spins. Feed is how fast it moves through the material. Depth is how much material it removes in one pass. These settings must work together. Too fast can burn the edge. Too slow can cause rubbing and poor finish. Too deep can push the tool off course. Too shallow can waste time without adding quality.

Chips carry away heat. Good chips look even and fall away from the cut. Bad chips clump or smear. Coolant helps remove heat and clears chips from the path. The right mix protects both the tool and the part.

Measuring to be sure the part is right

Cutting is only half the job. Measuring proves the part meets the drawing. Calipers and micrometers check diameters and thickness down to small fractions of a millimeter. Bore gauges check holes. Surface plates and height gauges help set heights and flatness. For complex shapes, a coordinate measuring machine (CMM) uses a probe to touch many points and compare them with the model.

Good measurement needs clean parts and a stable room. Dust or oil can trick a gauge. A hot part can read big; a cold part can read small. Shops often let parts sit to reach room temperature before final checks.

Why tiny tools power big machines

It is easy to focus on the huge machine body or the heavy table, but small tools are the real heroes. A new carbide end mill can run faster and hold size better than an old one. A stable tool holder cuts vibration. Shorter tool stick-out reduces chatter. These small choices change the whole process.

Take a gear housing for an e-bike motor. The housing needs smooth bores for bearings, clean threaded holes for bolts, and a flat face for the cover. If the boring tool drifts by a hair, the bearing may not seat. If a tap chips, a thread can fail. Strong machines help, but tiny tools make the final call.

Everyday products that depend on precision

Phones need exact camera mounts so lenses sit at the right distance. Game controllers need clean pivots so buttons feel crisp. Car brakes need bores with tight tolerances so seals hold pressure. Medical parts demand smooth edges and clean surfaces so they do not harm tissue. In all cases, better precision brings longer life, safer use, and a nicer feel.

Even simple items gain from accuracy. A scooter clamp must hold a tube without slipping. If the clamp bore is too large, it slides. If it is too small, the tube scratches or will not fit. A well-cut bore with a smooth finish makes the clamp strong and easy to adjust.

Common problems and how shops prevent them

Tool wear creeps in slowly. The part may look fine at first, then finish gets dull, and sizes drift. To stay ahead, shops track tool life by time or number of parts. They change tools before failure, not after. Vibration—called chatter—leaves a wavy pattern on walls and sounds harsh. Shorter tools, tighter holders, and better speeds calm chatter. Heat can warp parts and tools; coolant and smart chip control fix that.

Setup mistakes also cause trouble. If a part is not clamped square, every cut copies the error. Good fixtures hold parts the same way each time. A simple pin and clamp system can save hours of rework. Before the first real cut, many teams run a dry test in the air to confirm the path and clearances.

Teamwork between people, machines, and data

Strong results come from people who plan, measure, and adjust. Programmers build tool paths that respect the part. Operators listen to the cut, watch chips, and feel for vibration. Inspectors verify that numbers match the drawing. The data from measurement goes back to the program for small tweaks. That loop repeats until the part hits every target.

Shops also track trends over many jobs. Which tool lasts longest in a given alloy? Which holder resists pull-out? Which coolant mix stays clean? Small lessons add up. Over time, the process gets faster while quality stays steady.

Looking ahead: smarter tools, cleaner cuts

Cutting tools keep getting better. New coatings handle heat and reduce wear. Holders with anti-pull features stop end mills from slipping. Probes inside machines check parts between steps and feed the results to the control. Even 3D printing joins the process. A rough shape can be printed, then a CNC machine finishes the critical surfaces to tight size and smooth finish. This mix saves time and material for complex parts.

Sustainability also matters. Cleaner coolants, chip recycling, and energy-aware programs help shops reduce waste without giving up accuracy. Better planning means fewer scrapped parts and less rework. Precision, in the end, saves resources as well as time.

A simple next step

Tiny tools set the standard for big machines. Precision starts with smart tool choice, the right speeds and feeds, and a stable setup. Careful measurement confirms the result. When every step respects the target size, parts go together with ease, run smooth, and last longer.

Curiosity helps. The next time a device feels solid in the hand or runs quietly, consider the small details that made it happen. Ask questions, watch a machining video, or study a part drawing. Understanding how tiny tools shape big machines makes every product in daily life a bit more interesting—and a lot more impressive.